We develop innovative, patented technology designed to optimize the productivity of filling lines.

Traditionally, the beverages industry fills containers through a fluid mixing process. Novusfill, instead, designs, produces and commercializes technology that use an innovative system of "fluid integration".

Our technology is disruptive and triggers a change of paradigm that represents a quantum leap for the filling industry which is still using patents from the 1970's.

In addition to quantifiable economic and financial gains, our technology generates huge benefits for the environment given its efficient use of CO2, energy and water.

Our equipment can be used both on new production lines as well as on fully operational ones.

Instead of merely mixing fluids, we have patented a totally new way of preparing beverages that we call Fluid Integration Technology (FIT) which actually "integrates" all required elements like syrup, concentrate, water, juices, alcohol and carbonic gas.

The existing norm in the industry uses 1970's technology which relies on pumps to generate a turbulent flow in order to obtain homogeneity, a process that creates inherent instability and incorporates oxygen into the beverage, therefore reducing its quality and potential product shelf life.

Our devices operate integrating through the lamination of the fluids (solvent & solute) at very high speeds, increasing the contact surface to the maximum operating potential.

The higher fluid speed is achieved without reducing its kinetic energy. This changes the superficial tension of the molecules resulting in higher fluid density.

At higher density, permeability and retention capabilities are improved, producing a much better quality and efficiency of the beverage.

Our devices can be easily installed by simply replacing the traditional mixer in the production line.

On newly planned lines, our technology can be incorporated at inception.

SIFIT® (Single Fluid Integration Technology) a system which main process is the Continuous Integration of Carbonic Gas in beverages.

Unlike conventional systems, the integration of fluids is a unique and patented technology that allows this system to achieve performance of over 97% in the integration of Carbonic Gas.

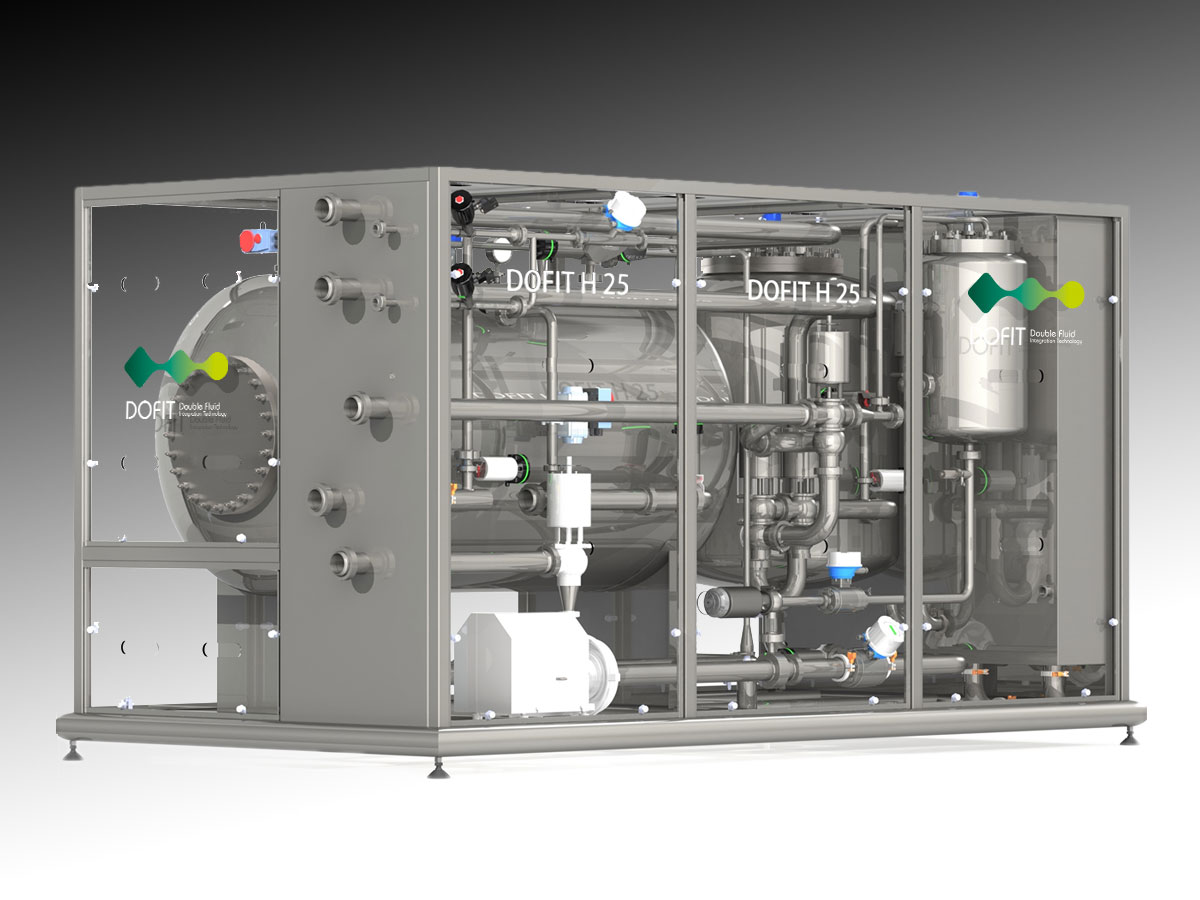

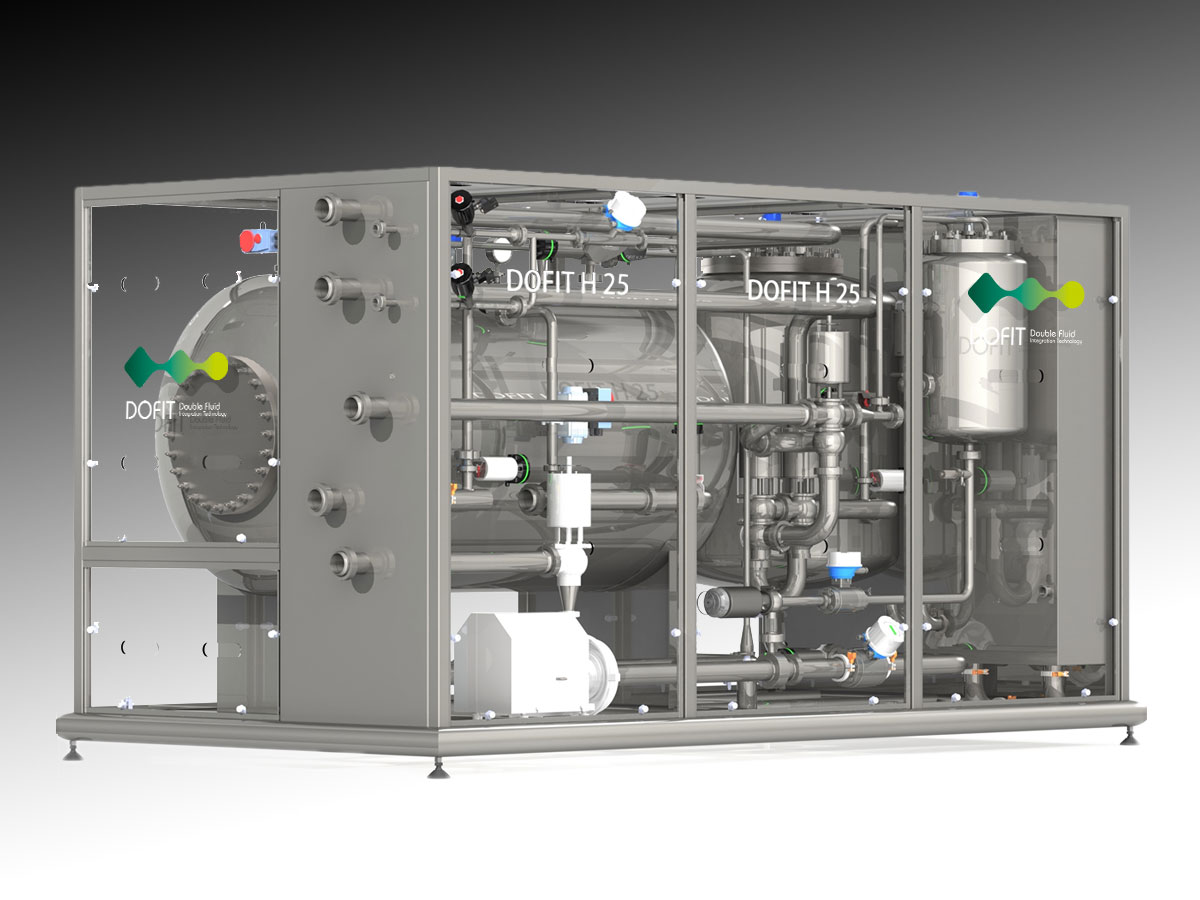

DOFIT® (Double Fluid Integration Technology) a system which main process is the Continuous Integration of syrup, juice, concentrate, water, alcohol and carbonic gas.

Unlike conventional systems, the integration of fluids is unique and patented technology that allows this system to achieve performance of over 97% in the integration of carbonic gas as well as 99,9% in syrup.

• We manufacture our equipment both

in Spain and Argentina.

• Manufactured under international standards.

• Hygienic design.

• Top brand components.

• Easy to implement.

• Friendly to use

• Lead time: 1 week.

• Proprietary software.

• Quick up & down stream communication.

• Flexible, adaptable and compatible.

• User friendly.

• Simple to operate.

• Flexible to produce different types of products.

• Easy maintenance.

• Ability to handle all process variables.

• Provides precise warnings,

• User friendly.

• Simple and Efficient customer service,

• Affordable and Competitive..

• Software can be updated remotely.

• Troubleshooting support remotely as well..

PRODUCTIVITY INCREASE |

44% |

PLAYBACK |

8 to 14 months |

Previous Equipment (avg) |

DOFIT RESULTS |

||

Filling Speed |

173 bpm |

250 bpm |

|

Filling Temperature |

4°C |

12°C |

|

Mechanical Efficiency |

95% |

98.2% |

|

CPK |

>1 |

<1.85 |

|

Impact on Efficiency |

|||

Excess of Foaming |

3% |

0.5% |

|

Lack of Refrigeration |

6,1% |

0,20% |

|

Waste of CO2 |

33% |

16% |

PRODUCTIVITY INCREASE |

33% |

PLAYBACK |

6 to 12 months |

Previous Equipment (avg) |

DOFIT RESULTS |

||

Filling Speed |

150 bpm |

200 bpm |

|

Filling Temperature |

2°C |

10°C |

|

Mechanical Efficiency |

89% |

98% |

|

CPK |

<0,8 |

<1.4 |

|

Impact on Efficiency |

|||

Excess of Foaming |

4,2% |

0.8% |

|

Lack of Refrigeration |

2,5% |

0,3% |

|

Waste of CO2 |

77% |

12% |

Previous Equipment (avg) |

SIFIT RESULTS |

||

Filling Speed |

225 bpm |

250 bpm |

|

Filling Temperature |

4°C |

14°C |

|

Mechanical Efficiency |

94,5% |

99,8% |

|

CPK |

<1 |

<2,1 |

|

Waste |

|||

Excess of Foaming |

6,5% |

0.5% |

|

Lack of Refrigeration |

2,5% |

0,1% |

|

CO2 |

20% |

3% |

PRODUCTIVITY INCREASE |

11% |

PLAYBACK |

6 to 12 months |

Installed Equipment Stds |

SIFIT RESULTS |

||

Filling Speed |

1100 cpm |

1250 Lpm |

|

Filling Temperature |

16°C |

23°C |

|

Mechanical Efficiency |

94% |

99,8% |

|

CPK |

Less than 1,33 |

Greater than 2,4 |

|

Waste |

|||

Excess of Foaming |

NA |

||

Lack of Refrigeration |

NA |

||

Waste of CO2 |

20% * |

3% |

* Standard CO2 waste in alternative equipment.

This canning line has NO Warmer and its staffing are two technicians

PRODUCTIVITY INCREASE |

13% |

PLAYBACK |

6 to 12 months |

Sarmiento 459,

6° piso,

CABA (C1041AAI),

Buenos Aires

Argentina

T (+54) 11 5278 3461

E info@novusfill.com